Primary Calibration

- Acoustics and Vibration Metrology

- Dimensional Metrology

- Electricity, Magnetism, and Electromagnetic Metrology

- Flow & Energy Metrology

- Mechanical Metrology

- Medical & Chemistry Metrology

- Optical Radiation Metrology

- Thermometry Metrology

Secondary Calibration

- Acoustics and Vibration Metrology

- Dimensional Metrology

- Electricity, Magnetism, and Electromagnetic Metrology

- Flow & Energy Metrology

- Mechanical Metrology

- Medical & Chemistry Metrology

- Optical Radiation Metrology

- Thermometry Metrology

Testing

- Acoustics and Vibration Metrology

- Dimensional Metrology

- Electricity, Magnetism, and Electromagnetic Metrology

- Flow & Energy Metrology

- Mechanical Metrology

- Medical & Chemistry Metrology

- Optical Radiation Metrology

- Thermometry Metrology

- FPD Testing

Solar PV

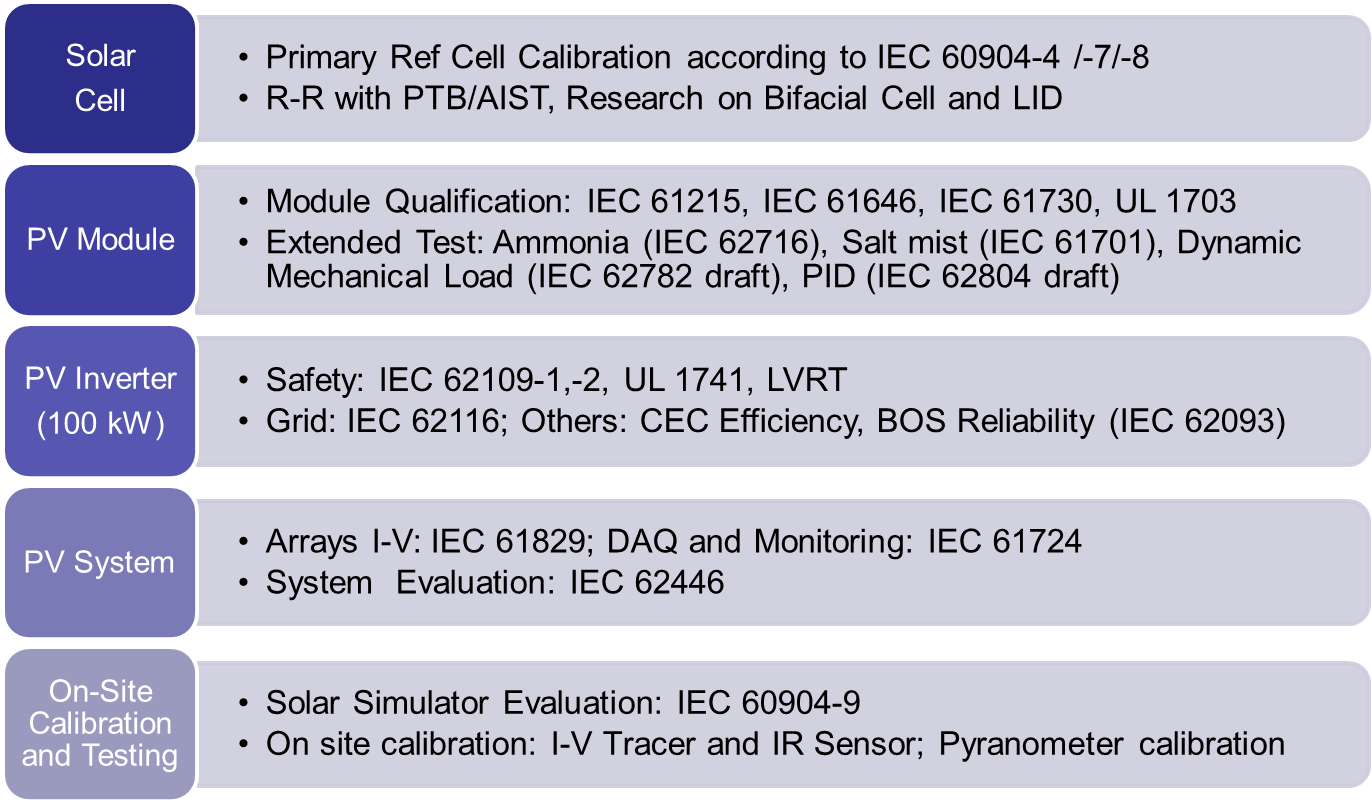

Photovoltaic Test Laboratory

Under the support by the Bureau of Energy and the Ministry of Economic Affairs, the Industrial Technology Research Institute (ITRI) established the first IECEE certified Photovoltaic Testing Laboratory in Taiwan. Specific equipment and technologies have been developed by ITRI for PV performance and safety tests, which are performed according to IEC PV standards.

Lab Capacities

UL 1703

Tests according to UL 1703: “Flat-Plate Photovoltaic Modules and Panels”.

UL 1703, the Standard for Safety of Flat-Plate Photovoltaic Modules and Panels details UL's current product requirements for this category of equipment.

- Performance

- Electric Safety (Leakage Current, Dielectric Voltage-withstand, Bonding Path Resistance)

- Mechanical Safety (Impact, Mechanical Load, Push Test, Cut Test)

- Climate (Humidity, Temperature Cycling, Accelerated Aging, Water Spray)

- Fire Hazard (Temperature Test, Reverse Current Overload, Hot-spot Fire Test)

Performance measurement

We measure the performance of PV cells and modules with respect to standard testing conditions—defined as a reference temperature (25°C), total irradiance (1000 W/m2), and spectral irradiance distribution (IEC standard 60904-3).

Accelerated test

We provide several accelerated tests to evaluate quality of PV module or design specific test procedure for customer.

- PID (Potential Induced Degradation)

- 2000/3000 hrs damp heat test

- 200/400/600 thermal cycling test

- Light soaking + damp heat test

- long term 2kW outdoor field testing in Ping-Dong

IEC 61215

Tests according to IEC 61215, "Crystalline Silicon Terrestrial Photovoltaic (PV) Modules - Design Qualification and Type Approval“. It describes various qualification test methods of the properties of the modules based on simulating the operating environment under controlled conditions. They can be put into the following categories:

- Electric properties of PV module (STC performance, NOCT, Temperature Coefficient, Low Irradiance, Bypass Diode, Insulation)

- Reliability (Hot-spot, UV)

- Climate (Thermal Cycle, Damp Heat, Humidity Freeze)

- Mechanical (Mechanical Load, Hail)

The tests are passed, if no major visual defect is found, and the output power differs with its initial value less than a defined amount after the testing procedure. The IEC 61215 qualification certificate has gained acceptance over past few years as the quality symbol for crystalline PV modules.

IEC 61646

Tests according to IEC 61646, "Thin-Film Terrestrial Photovoltaic (PV) Modules - Design Qualification and Type Approval“. The IEC 61646 for thin-film PV modules is in many aspects identical to the international standard IEC 61215 for crystalline modules. The main differences between the two standards lie in the additional testing procedures adapted to the special properties of thin-film technologies. These additional tests take the degradation behavior due to the exposure of sunlight into account.

IEC 61730-2

Tests according to IEC 61730 “Photovoltaic (PV) Module Safety Qualification”. As the aforementioned qualification standards do not sufficiently cover aspects of personnel protection, IEC 61730 was released.

The standard consists of two parts:

part 1: Requirements for construction; and

part 2: Requirements for testing.

IEC 62108

Tests according to IEC 62108, “Concentrator Photovoltaic (CPV) Modules and Assembles – Design Qualification and Type Approval”. This standard is similar to the qualification standards for the crystalline (61215) and the thin-film modules (61646). Due to the partial high concentration of the solar irradiance through lenses or mirrors, the thermal stress on the equipment can be high. A separate safety standard is currently under development.

EL imaging

Silicon solar cells emit light when excited with light or voltage. The emission is caused by a band-to-band transition, and is a relative measure of the minority carrier diffusion length. Areas of silicon with along diffusion length have brighter luminescence and higher efficiency. Therefore, the luminescence image is a rapid and direct measure of the overall cell efficiency and a map of any cell defects.

IEC 61701 Salt mist corrosion

Tests according to IEC 61701: “Salt mist corrosion testing of photovoltaic (PV) modules“. For PV modules operating in a highly corrosive atmosphere throughout their lifetime, the resistance against such effects should be tested. A salt mist corrosion test standard is therefore established for PV modules that are installed near coasts or in maritime applications. Similar to the other qualification standards, minimum passing requirements for the electrical properties of the modules are described.

Vibration test for Transportation

This test can evaluate the influence of packaged design for PV modules under transporting environment and investigates the power drop of photovoltaic modules (PV modules) during vibration test which simulated transporting situation. This method was developed to a SEMI standard (4997) and be accepted in 2011.

Simulator Performance

Tests according to IEC 60904-9, "Photovoltaic devices - Part 9: Solar simulator performance requirements“.

The purpose of this standard is to define classifications of solar simulators for use in indoor measurements of terrestrial photovoltaic devices, solar simulators are classified as A, B or C for each of the three categories based on:

- Spectral distribution match

- Irradiance non-uniformity on the test plane

- Temporal instability.

Test devices of our evaluation service includes large area or table type and flash or continuous type solar simulator; our fast solar simulator non-uniformity system provide customized service which is suitable for convenient routine inspection and testing.

Reference cell calibration

- Spectral Responsivity (SR) Systems

Tests according to IEC 60904-8, " Part 8: Measurement of Spectral Response of a Photovoltaic (PV) Device” Design qualification and type approval“. Spectral responsivity systems measure how a device responds to selected narrow (spectral) bands of irradiance. Responsivity is measured in units of AW-1 versus wavelength and reported in terms of quantum efficiency (QE)—a measure of how efficiently a device converts incoming photons to charge. Our systems measure the spectral response at wave length range (300 - 1700 nm), resolution (5 nm), spot light (1.5 mm X 1.5 mm), and different chopping frequencies (4 to 100 Hz).

- Solar Cell I-V measurement

I-V measurement systems determine the output performance of devices, including: open-circuit voltage (Voc), short-circuit current (Isc), fill factor (FF), maximum power output of the device (Pmax), voltage at maximum power (Vmax), current at maximum power (Imax), and conversion efficiency of the device (η).

Our cell I-V measurement is suitable for secondary reference cell calibration calibrated by our primary reference cell. We also provide measurement service of non-packaged cell by probe stations.

Files: Services of PV Testing/Calibration Lab and Contact Windows (PDF)(Download)

Contact:

Project Manager: Min-An Tsai (蔡閔安)/ +886-3-5918097/ MATsai@itri.org.tw

Lab Head: Hung-Sen Wu (吳鴻森)/ +886-3-5913899/ wuhungsen@itri.org.tw

TEL: +886-3-5913881, Fax: +886-3-5837801

Rm. 168, Bldg. 21 , 195, Sec. 4, Chung Hsing Rd., Chutung, Hsinchu,Taiwan 31040, R.O.C.

LED and Lighting

- Advanced Opto-Mechatronic Technology

- Accelerated LED lifetime test by using pulsed current technology

- Rapid light intensity distribution measurement technology and patent

- Rapid total luminous flux measurement technology and patent

- Safety and Performance Testing Lab

- For domestic standard:CNS Mark、MIT Mark and Green Mark

- For international standard:CQS Mark、Energy Star Mark and IECEE Mark

- Instrument and Software development for optical testing system

- Self-made accelerated luminaire degradation test system

- Self-made LM82 test system

- Self-made sun phantom test system

- Self-made traffic light test system

Files: Services of LED Testing/Calibration Lab and Contact Windows(DOCX)(DOWNLOAD)

Displays

- Testing, and Verification & Validation (V&V)

- Technology and Product Development

- Information and Consultation

Gas and Environmental Chemistry

AOI Module/Equipment

Medical Device

- Regulatory support

- Medical device testing and evaluation support

- Evaluation technology and tools development

- Training and information support